I have done a few PCBs using the reflow process. To apply the solder-paste using a stencil one requires some sort of fixture to hold the PCB.

So far I helped myself with other PCB Material which I glued on the table to get to the same height. This is okay when only one PCB needs to be made. However, when doing multiple PCBs on after another, the position needs to be constant for every board.

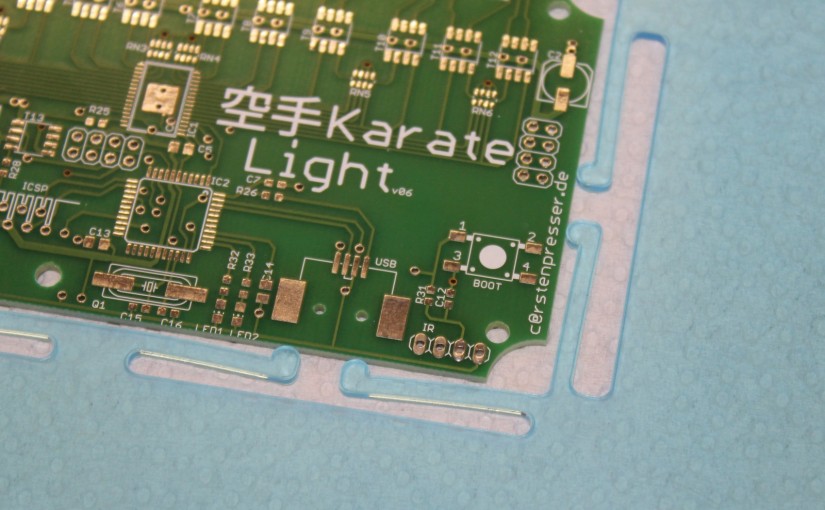

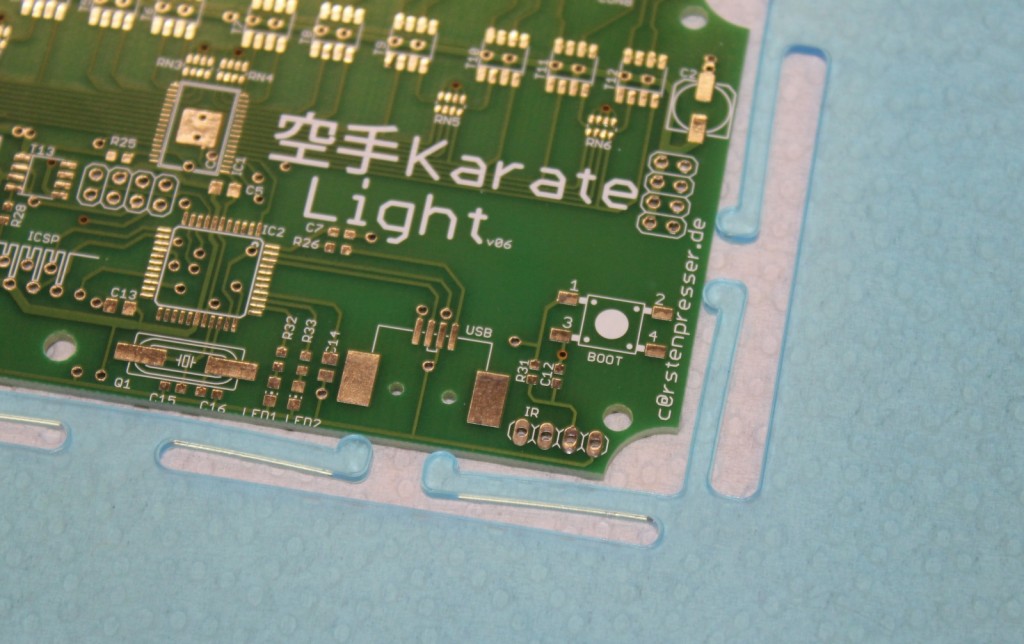

So I designed a simple spring loaded fixture to hold the PCB in place. Its made out of 1.5mm acrylic.

6 thoughts on “PCB fixture for applying solderpaste”