Ikea does sell a reasonably nice Ringlight called ‘LÅNESPELARE’. It runs of 5V and has a USB-A-Plug for its supply. A simple controller is build into the cord. Unfortunately, it does not remember its last setting/power status after it has been unplugged. If I switch it off via my home-automation using a zigbee outlet, I always need to also switch it on using its own controller. That kinda defeats the whole idea.

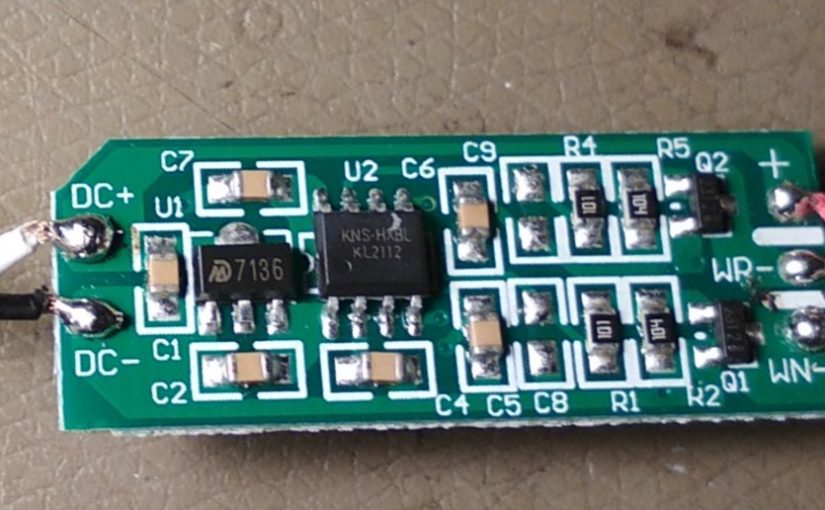

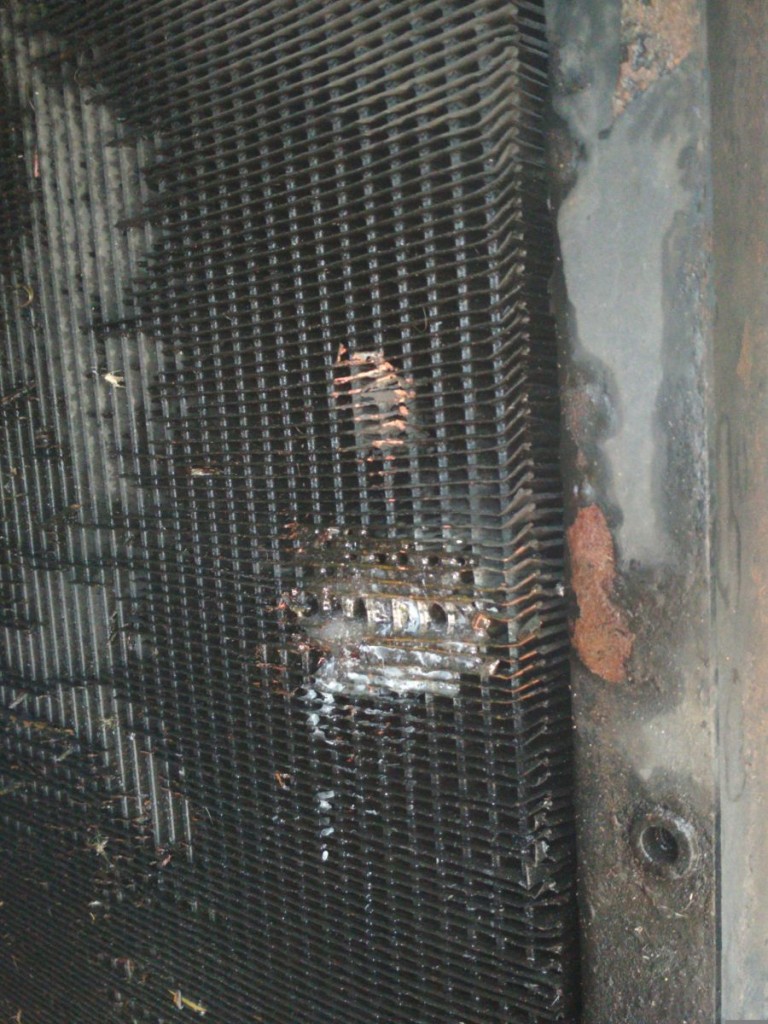

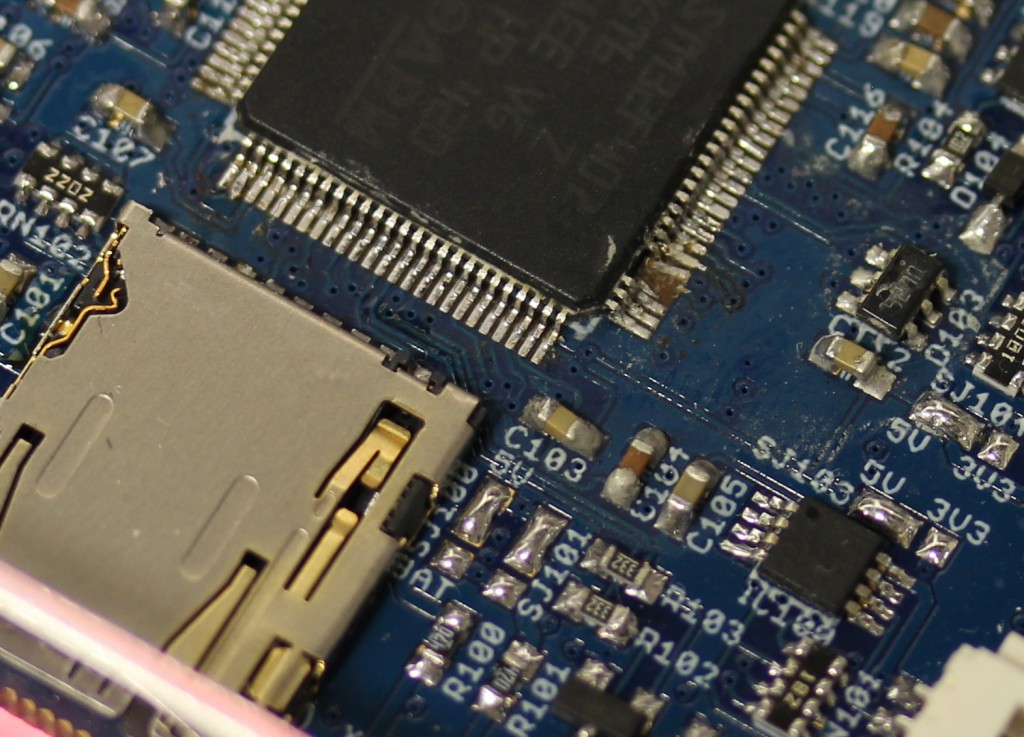

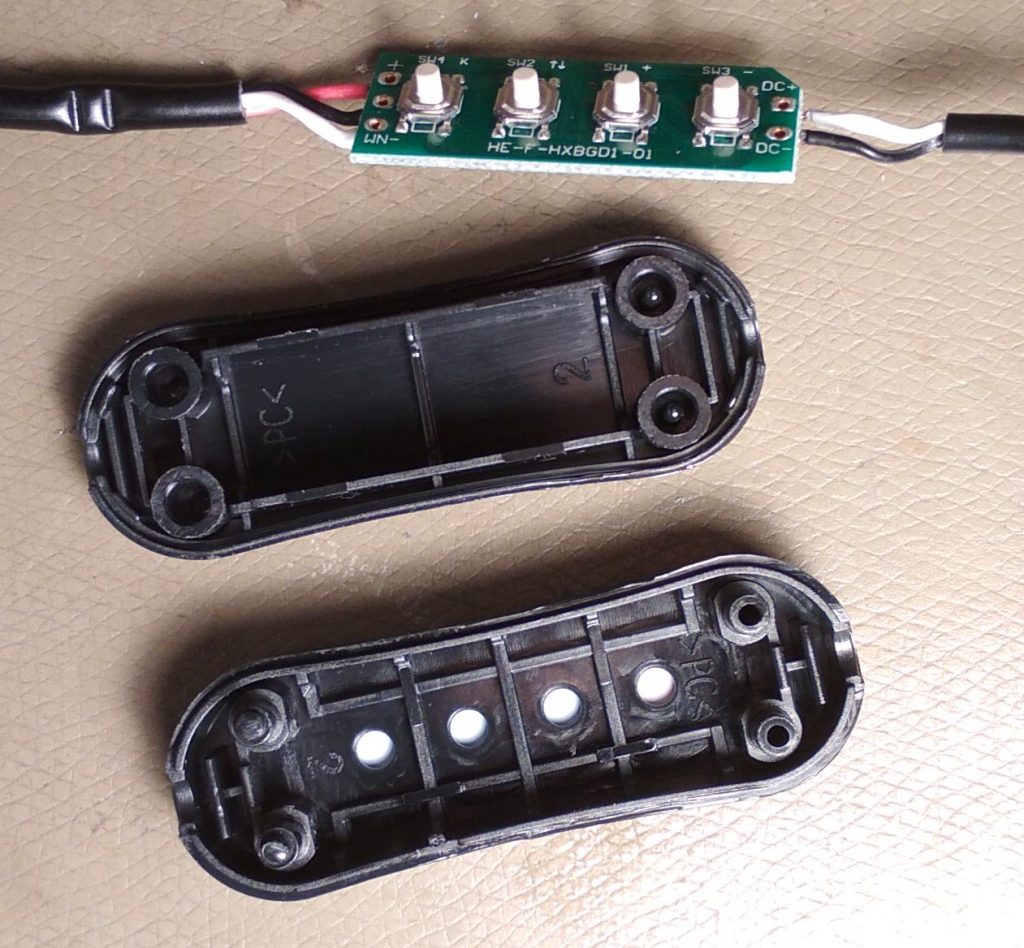

The case does not open that easy. I had to use some force, but managed to not break it. Perhaps the left domes have been welded, I heard a crack when I finally got it open.

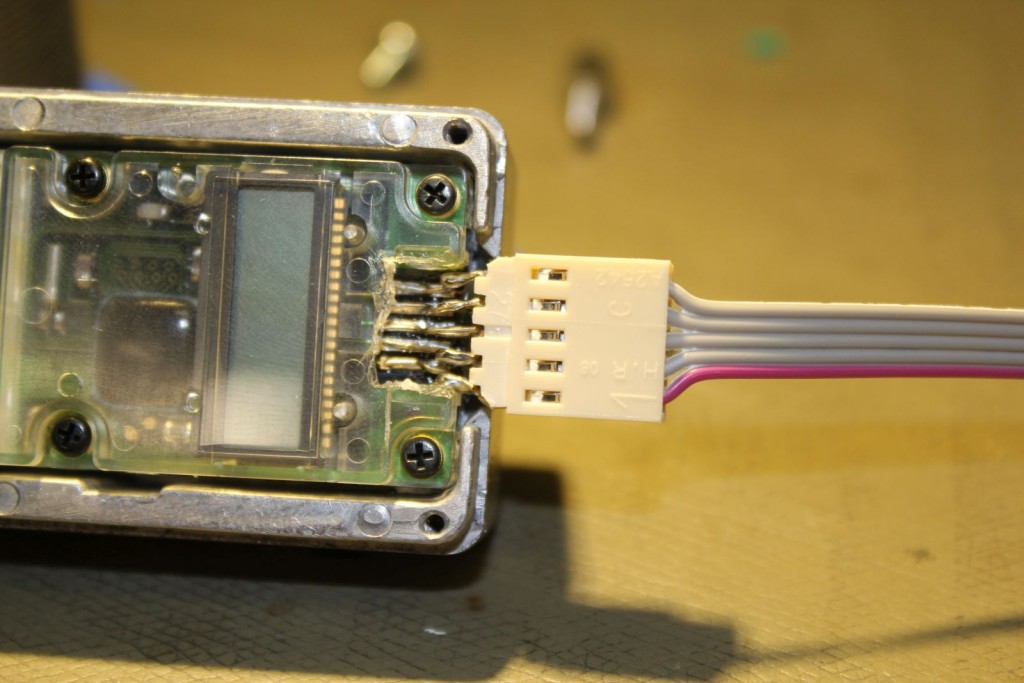

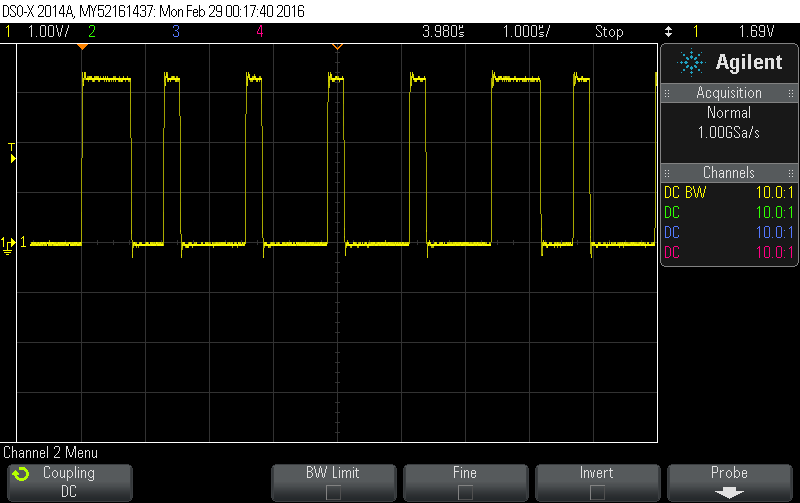

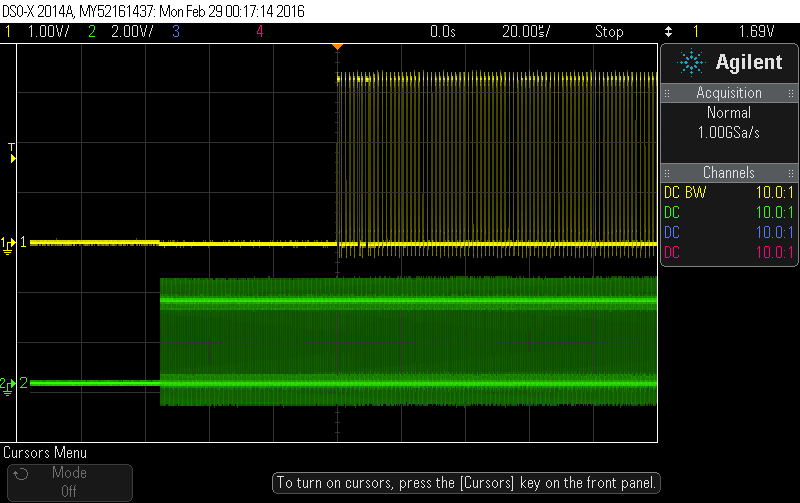

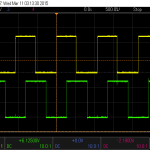

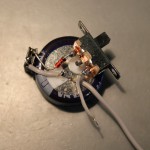

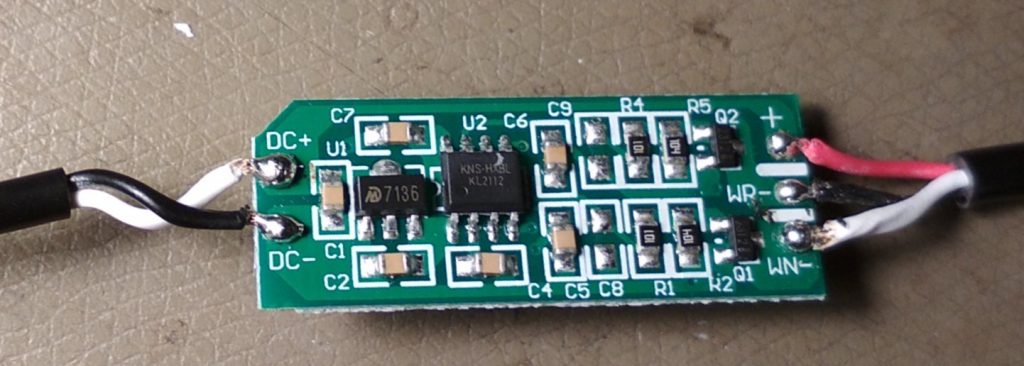

The original controller is pretty straightforward. It has a LDO (U1, “7136”, SOT-89 package) some kind of microcontoller (U2, SO-8 package), and two output transistors. One for Warmwhite and one for Coldwhite. The slikscreen reveals that those are low side switches. Seems like a simple PWM output.

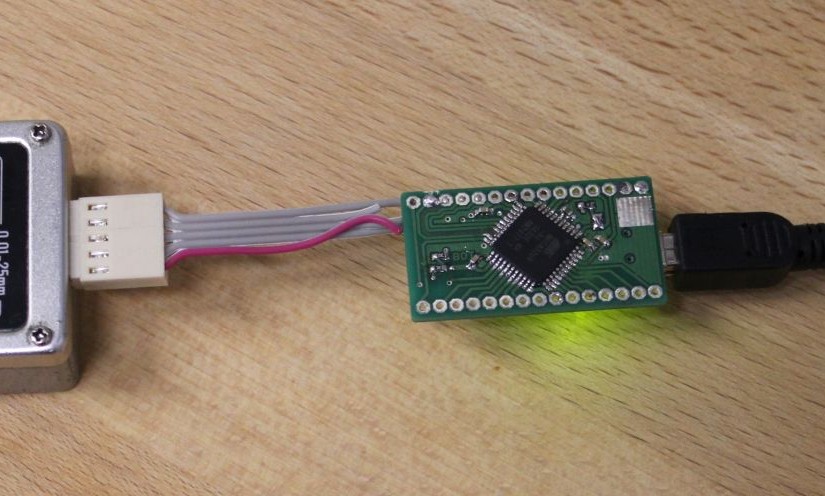

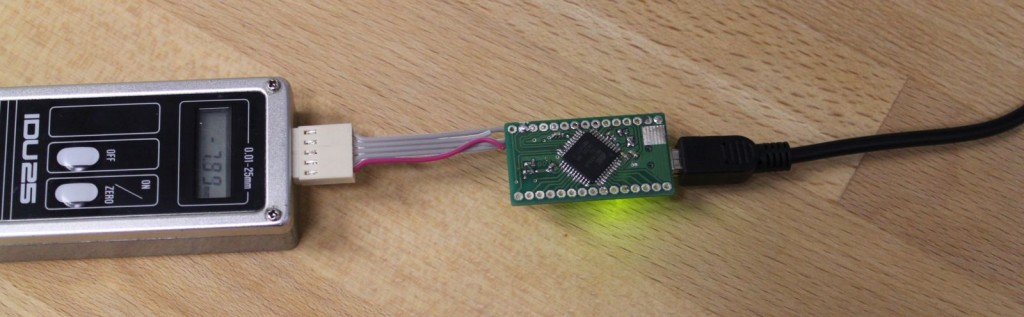

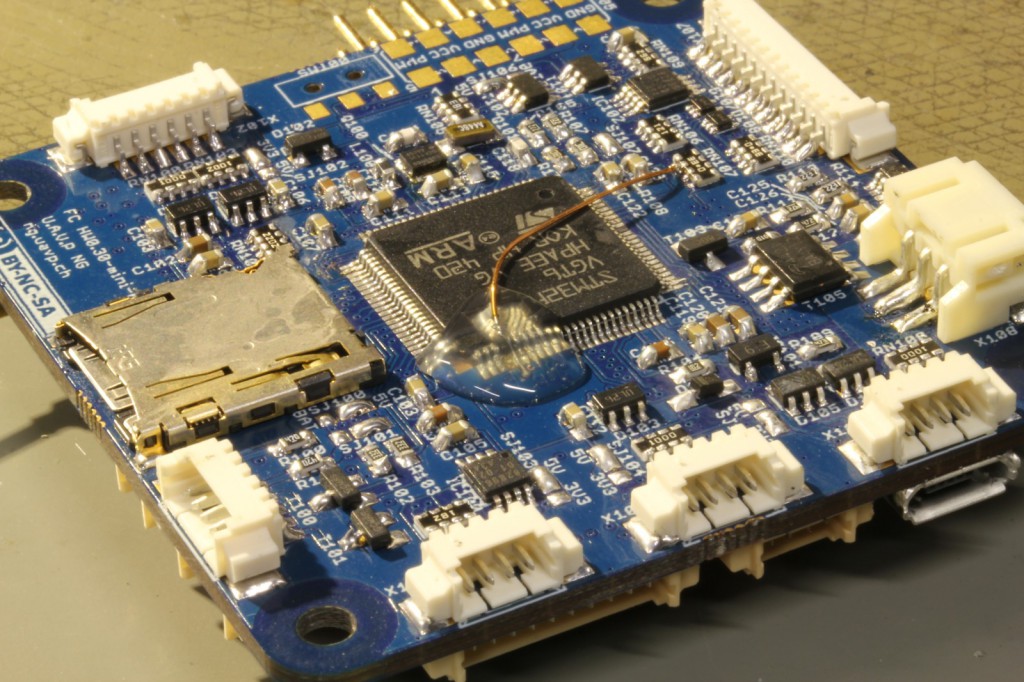

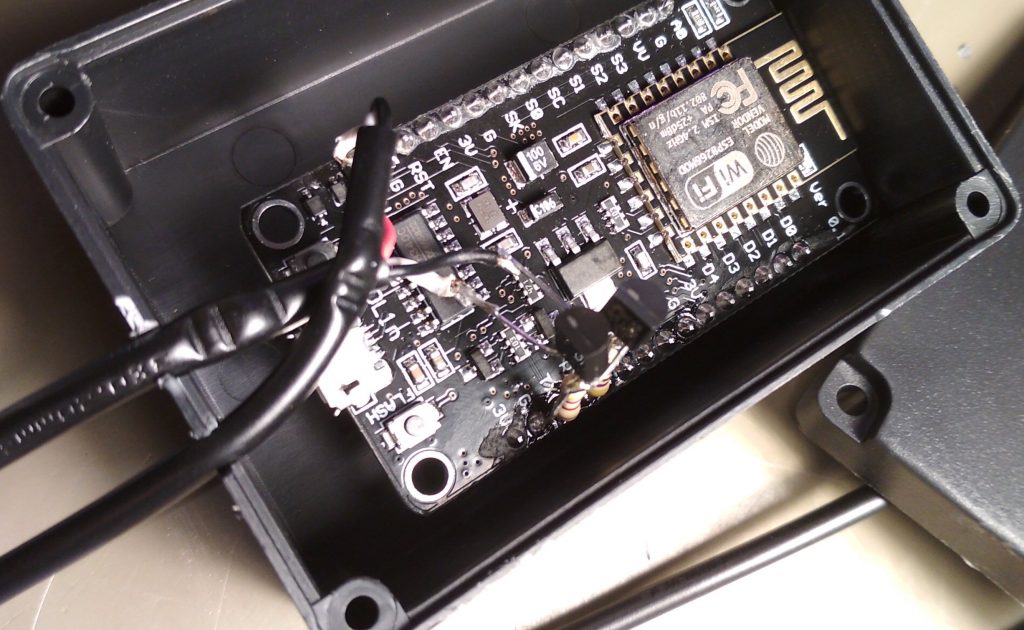

So we can replace it with another PWM controller. I choose to use https://github.com/Aircoookie/WLED since it integrates nicely into home-assistant. Its also really easy to configure and use. It already comes with a mode for PWM Output for warm/cold-white LEDs. All I had to do is to upload the firmware using esptool.py, no coding required at all. On the hardware-side two N-Channel-FETs (BS170) in TO-92 were used as low-side-switches. Then everything was fitted into a plastic case using excessive amounts of hot glue.

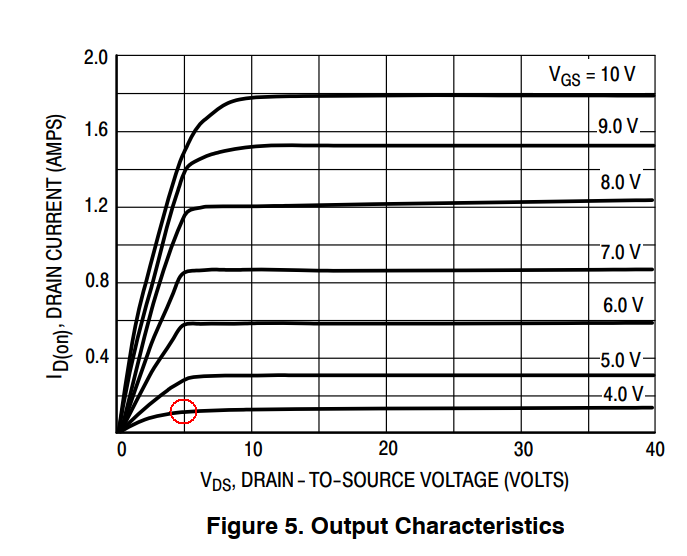

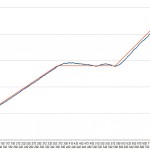

The BS170 is not the best FET for this application. Its Threshold-Voltage does not work well with the 3.3V of the esp8266. But those were the only available at the time. Below it the chart from its datasheet, with the working point circled in red. Perhaps I should just use the transistors from the original controller board 🙂