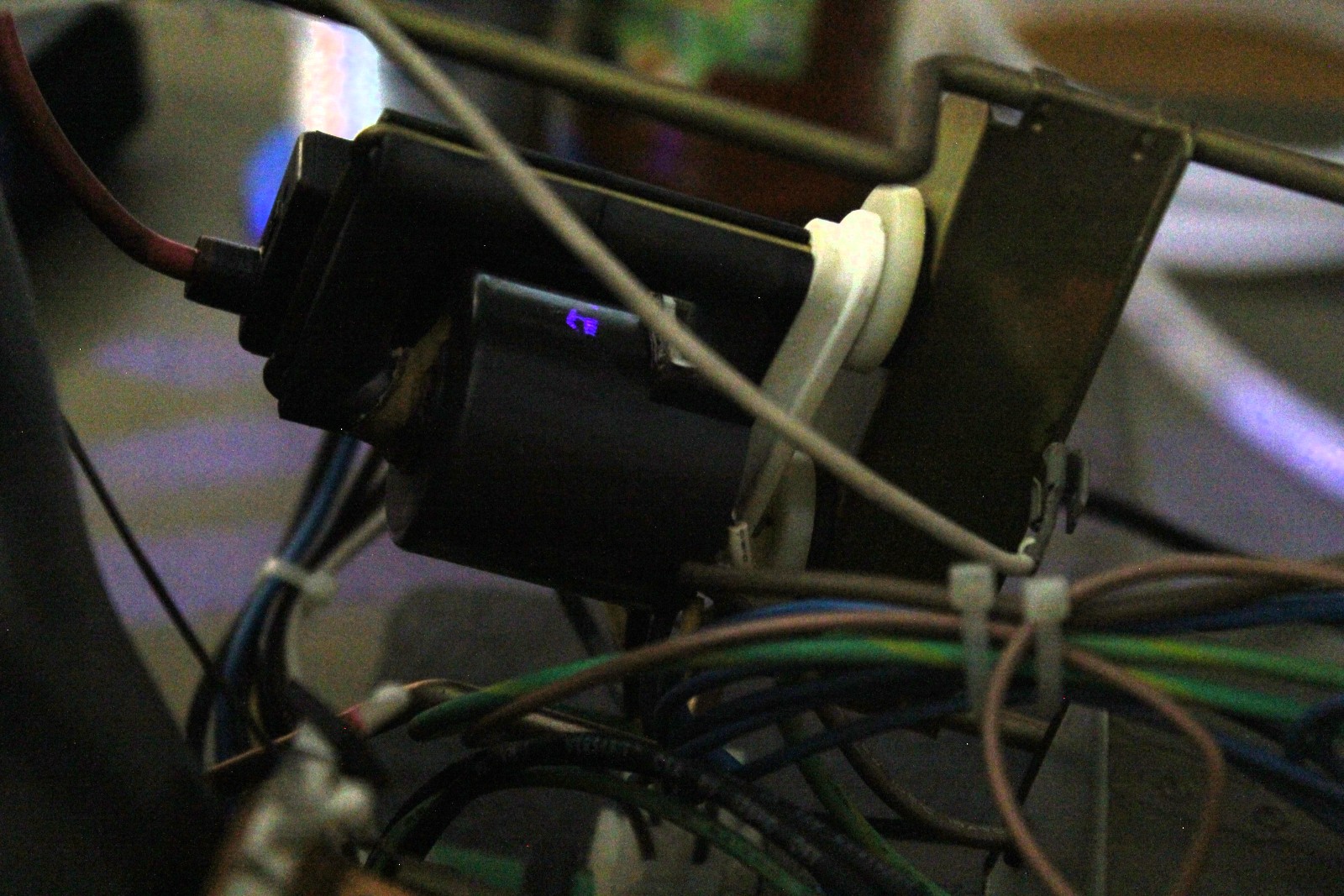

Unfortunately my VT220 did not work well. The flyback transformator is leaky. It can be heard and smelled (the ozone generated by the arc). In a low light environment the arc is also visible (blue-violet spot in the center of the picture).

Most resources on the internet suggest to just get a replacement. Some comments even say it is dangerous to try a repair, but fail to mention exactly why. Getting a replacement is pretty hard for such an old device. I checked the google-search, ebay and hr diemen. But I was not successful.

The I came upon this post on reddit/imgur: https://imgur.com/a/uEAlQ3j which tackles the same issue.

I choose to do something similar. Use epoxy to re-seal the transformer. But instead of brushing it on I wanted to add a thicker layer.

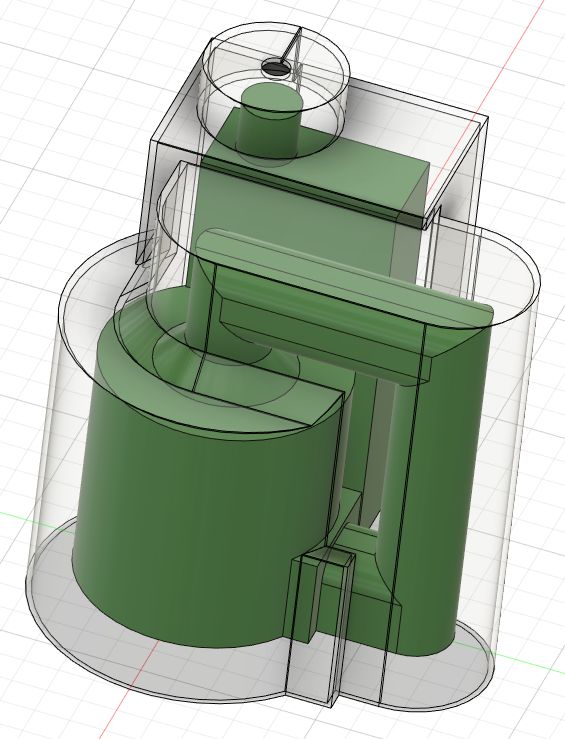

The first step was to make a rough 3D-Model of the existing transformer. Then offset it by 5mm outside to create a mold. That mold was printed in PLA.

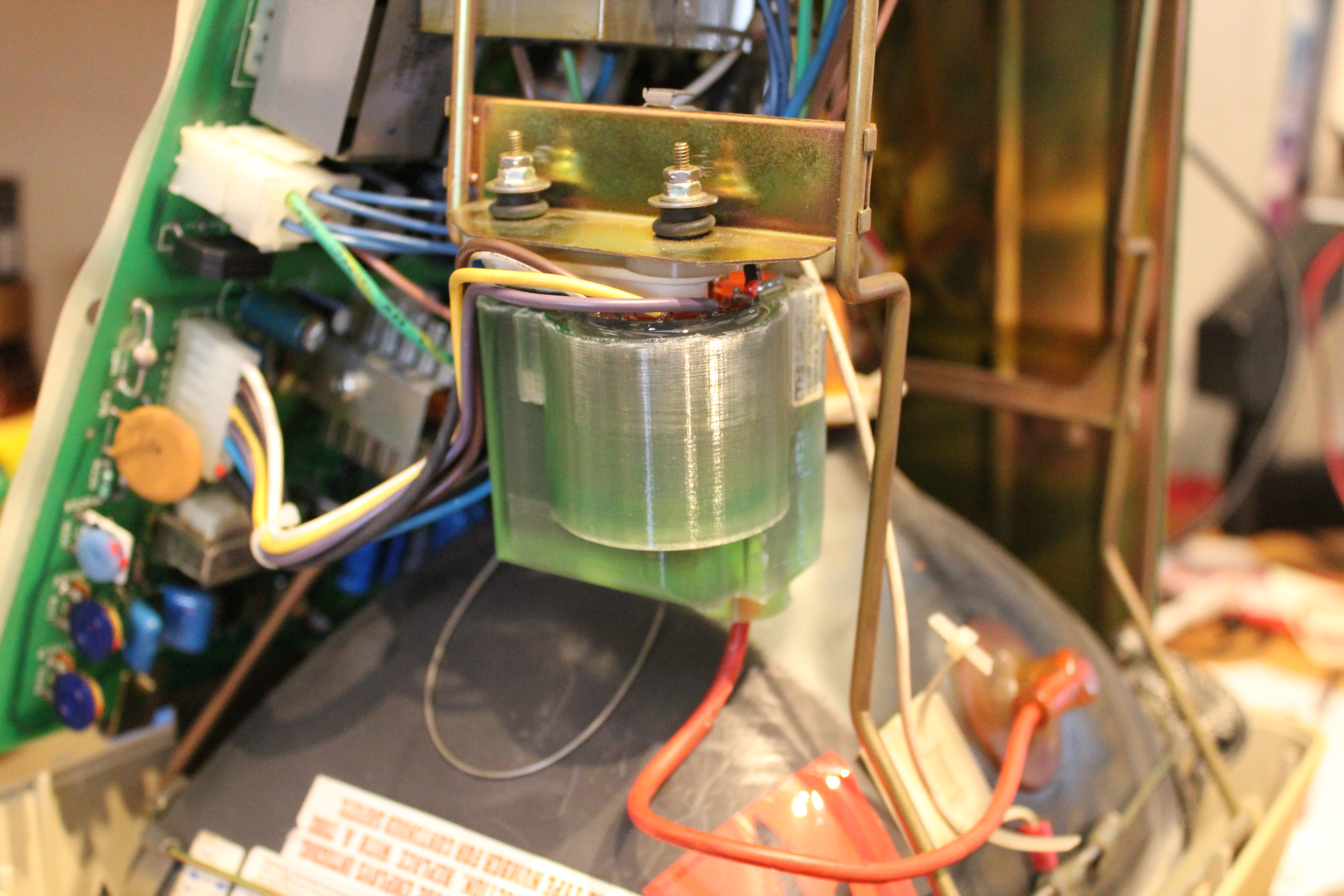

I did not take any pictures during the casting process. I used hot-glue to fix the flyback in the mold so it does not move while casting. The epoxy used was E45GB with some green pigment mixed in. The volume needed was extracted from the 3D-Model of the mold and the transformer. Make sure to factor in the density of the epoxy, I did not and had to mix a second smaller batch

As you can see above I did not remove the mold. Its fixed to the epoxy. Next time I will use a release agent.

But did it work? I would say yes. There is no more arcing and I cant smell any ozone anymore. It also more silent, but the typical 15kHz(?) noise is still present.

Sehr interessant … habe das selbe Problem mit meinem VT220. Hat sich die Lösung bisher bewährt?

Um ehrlich zu sein kann ich das nicht beantworten. Ich habe nach der Reperatur das VT220 nur circa 5 Minuten benutzt. Ich hab keinen schönen Platz in der Wohnung dafür, daher steht es aktuell doof rum.

Ich werde es aber mal länger anschalten und berichten.

The original question from ‘Conrad’ translates to “Did it work out reliably?”.

To test it, I did run the device for about 8 hours today. I can’t smell any ozone.

Unfortunately the 15kHz noise is still there. Next I will try to replace the rubber-dampeners on the flyback mount.

I suspect its impossible to get rid of it completely.